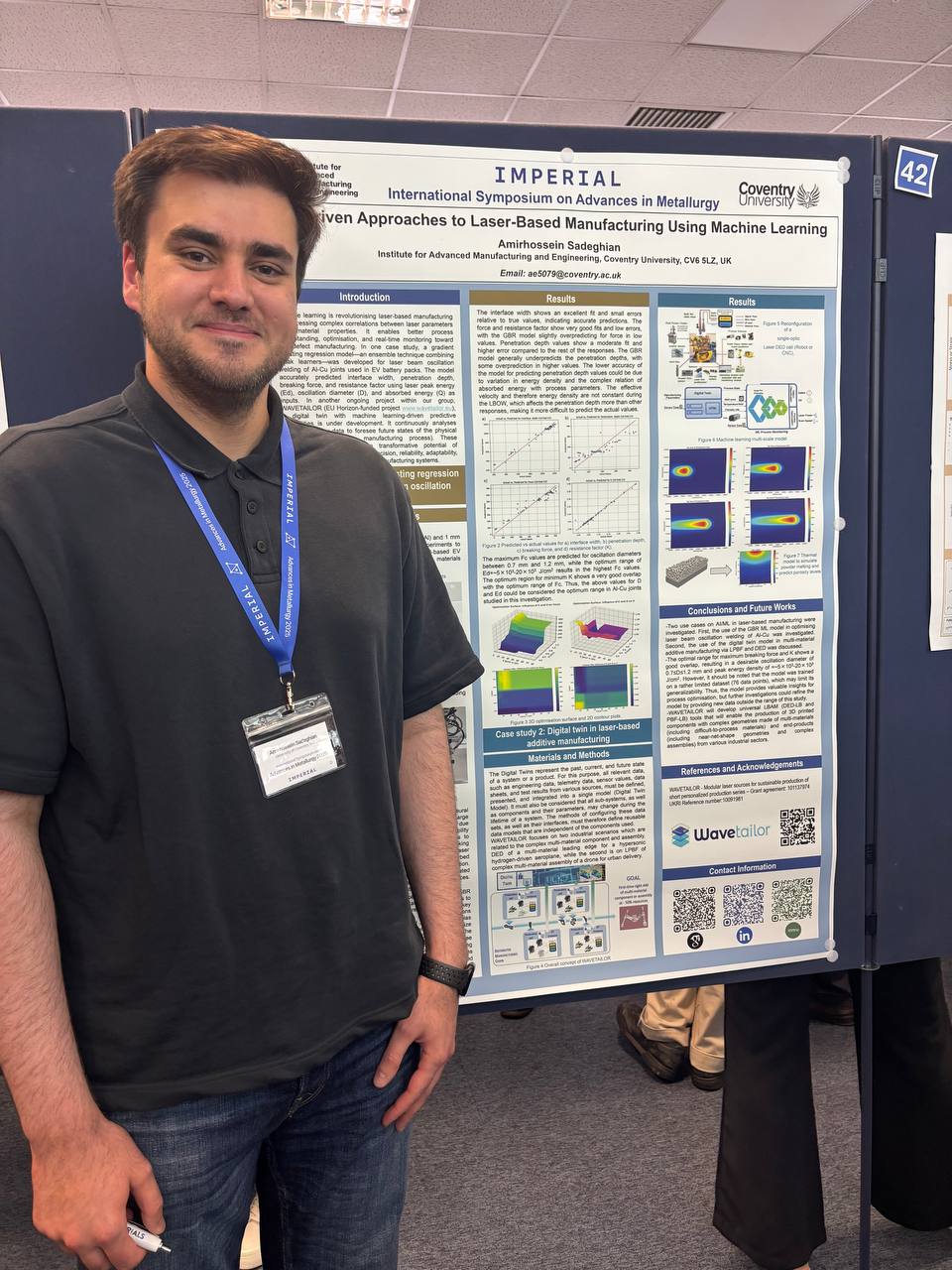

At the recent International Symposium on Advances in Metallurgy hosted by Imperial College London, Amirhossein Sadeghian from Coventry University presented his poster on “Data-Driven Approaches to Laser-Based Manufacturing Using Machine Learning.” This work, part of the Wavetailor EU project, drew attention for its innovative blend of laser processing and real-time AI-driven optimization.

By applying machine learning to sensor data from laser manufacturing processes, Amirhossein’s approach enables predictive control—minimizing defects and adapting on-the-fly to changing material conditions. His research represents a key step toward self-optimizing, intelligent production systems.

The poster explores:

- Real-time parameter control using AI.

-

Improved quality and consistency in alloy processing.

-

Scalable models for different materials and geometries.

Amirhossein’s work sparked strong interest from peers across metallurgy, AI, and laser engineering. As Wavetailor continues to bridge smart data and advanced manufacturing, this contribution showcases how machine learning can actively shape the future of materials processing.